Corian worktops: Why you should choose your installer wisely

Posted by Whitehall on 21st Dec

DuPont Corian ® worktops are one of the UK’s most sought after features in contemporary kitchen design. But for all their luxury charm, they are by no means the simplest surface to work with. As such, you need to choose your installer wisely.

Corian ® fabrication requires a specialist knowledge of the material, its properties and the correct handling processes, as well as access to industrial machinery.

While anyone can legitimately buy sheets of raw Corian ® and fit them using hand tools, the strength and finish of the worktop can be permanently damaged. Corian ® is a synthetic material and hand-held tools chip away at the surface’s fibres, causing hairline fractures that can deepen over time.

Because of this, only Corian ® worktops installed by DuPont certified fabricators come with a manufacturer’s warranty.

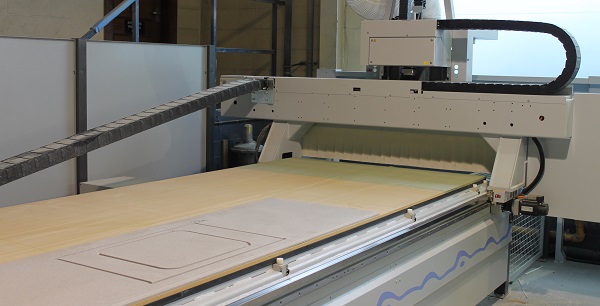

To meet DuPont’s quality standards, a worktop needs to be fabricated off-site using professional machinery, such as CNC cutting machines, industrial sanders and thermoforming equipment. This is the process we follow, which means that every Corian ® worktop we install is built at our facility and delivered in parts.

Corian ® fabrication is a precise process with multiple stages, so you might be left wondering what impact this has on your installation timeframes. But the simple answer is; none.

CNC industrial cutting machine

Our templating process has been designed to ensure your Corian ® worktop is exactly right first time around. This means we’re able to turn up, fit it and leave you to get on with the rest of your kitchen installation.

Without the luxury of working on-site, we have to pay incredible attention to detail from the earliest stages of your surface design project. Here’s how we get it spot on at each point:

- We quote accurately from your plans – we assess projects thoroughly in order to provide a clear price with no hidden costs.

- We complete a site visit – our engineers visit sites so that they can gain a better understanding of the project at hand and gather a series of detailed measurements.

- We build a precise template – using the plans we’re provided with and our engineers’ measurements, we create a detailed template that informs each element of the build.

- We accurately build your Corian ® worktop – paying attention to the closest millimetre, our engineers fabricate worktops from raw sheets of Corian ®.

- We seamlessly install your worktop – delivering the structure in parts, we slot surfaces into designs and secure them in place. (We leave a spare piece of Corian ® on-site in case of future repair work too).

- Your ten years’ manufacturer’s warranty begins – this means that for the next ten years, one of our engineers will be on hand carry out any repairs.

It may seem relatively simple, but our DuPont-approved process has been refined over 25 years to become as streamlined as possible. This not only enables easy installation but provides complete peace of mind for both you and your end customer.

While a non-specialist kitchen fitter or handyman may be able to install a Corian ® worktop that looks the part, neglecting the correct procedures will reduce the lifespan of the finished surface and ultimately damage your customer’s investment.

Want to find out more about Corian ® worktops for your projects? Contact us on 0113 222 3000 or complete the short form.

Back to blog