How our production process reinforces our Corian® solid surfaces

Posted by Whitehall on 26th JunFrom kitchens and bathrooms to prisons and laboratories, a stronger and more durable surface fabrication represents a better financial investment.

Corian® is widely accepted as one of the most hard-wearing synthetic solid surfaces on the market and it’s true that its unique properties make it extremely difficult to scratch and damage, and impossible to permeate.

However, a lesser known fact is that Corian® needs to be treated in very specific ways to secure its stability throughout the surface production process. Mishandling can cause lasting damage that will reduce the life-expectancy of the final product.

As expert surface fabricators, all of our processes are designed around preserving the strength of the raw materials in order to create the highest quality end-product.

To give you an idea of how we achieve this, here are five ways we reinforce the strength of our Corian® surfaces during production:

1. Curved and strengthened corners

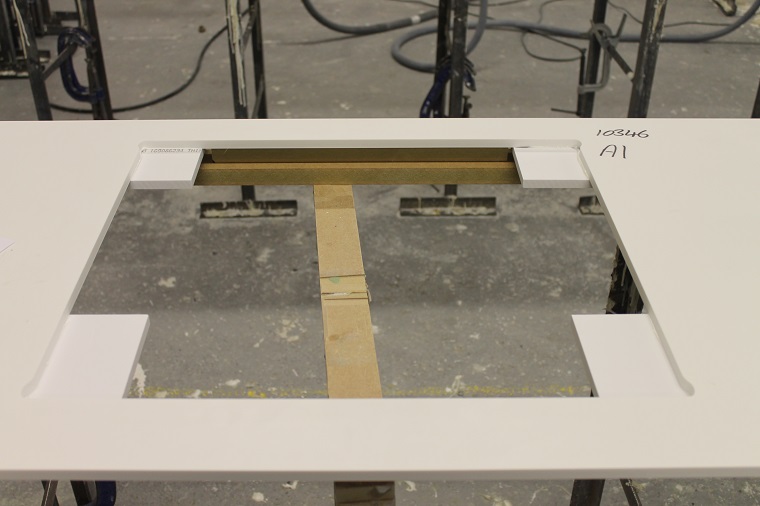

Wherever features like sinks, hobs or cable ports are added to a design, we need to cut away precise pieces of the surface to seamlessly accommodate them. These internal corners can create pressure points that can weaken the structure.

To avoid this, we reinforce every corner two-fold. Firstly, we cut the corner as a smooth bend rather than a sharp angular corner, as this creates tension that could result in a crack. Secondly, we reinforce that corner with a double-thickness support that will be invisible on completion.

2. Machine cutting on a CNC cutting machine

The right equipment is essential in ensuring your surface is cut to size accurately, the very first time. A Computer Numerical Control (CNC) cutting machine not only enables precision to the finest millimetre, but it also prevents any damage being done to the surface fabrication.

Using a regular saw on Corian or other synthetic materials creates rough edges and hairline fractures that could weaken your surface. The CNC machine eliminates this risk.

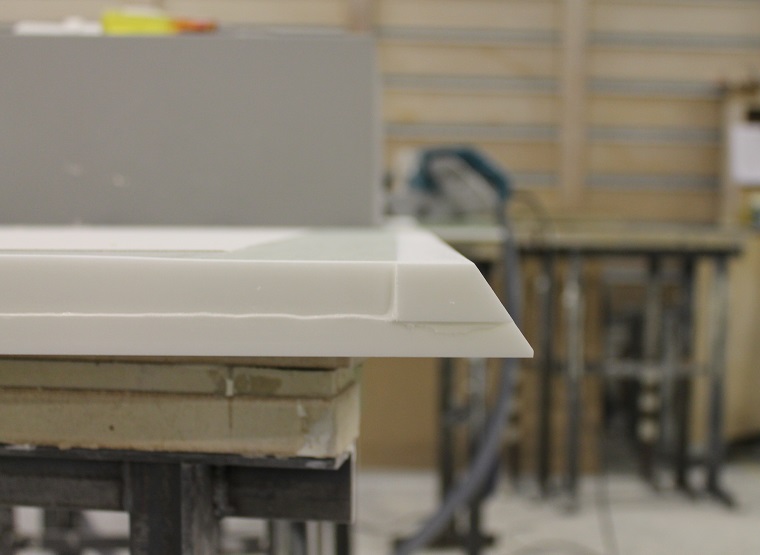

3. Heat moulding for curved edges

One of the key features that distinguishes Corian® from other materials is its thermoformability. Heating Corian® up to around 150°C, shaping and resetting it enables you to achieve sweeping curves and bends of all shapes and sizes. This creates a completely solid curved edge that will stand the test of time.

4. Corian®-based glue technology

The weakest point of any structure is its joins. Or is it? Manufacturer, DuPont, has developed a Corian®-based heated glue that, once dried, fuses the two surfaces together with a strength equal to the surface itself.

We set all of our joins with this glue, and then fix with clamps to solidify, forging joins so indestructible you wouldn’t know they ever existed.

5. Seamlessly-blended joins

In addition to using purpose-built glue, all of our joins are made seamless and inconspicuous. This means we can create increasingly complex surface systems that are successfully delivered and installed in one complete piece.

While these processes may seem detailed, they represent industry best practice. As members of the Corian Quality Network, our processes are regularly tested and monitored by DuPont technicians to ensure we are meeting the required standards.

It is this level of detail that has seen us become the only fabricator in the UK permitted to create surfaces durable enough for use within HM prisons.

Want unrivalled durability for your next installation? Talk to our experts about a Corian solid surface for your next project.

Back to blog